The Polyfloss Factory is a local plastic recycling system using the principle of COTTON CANDY to produce wool out of waste.

1

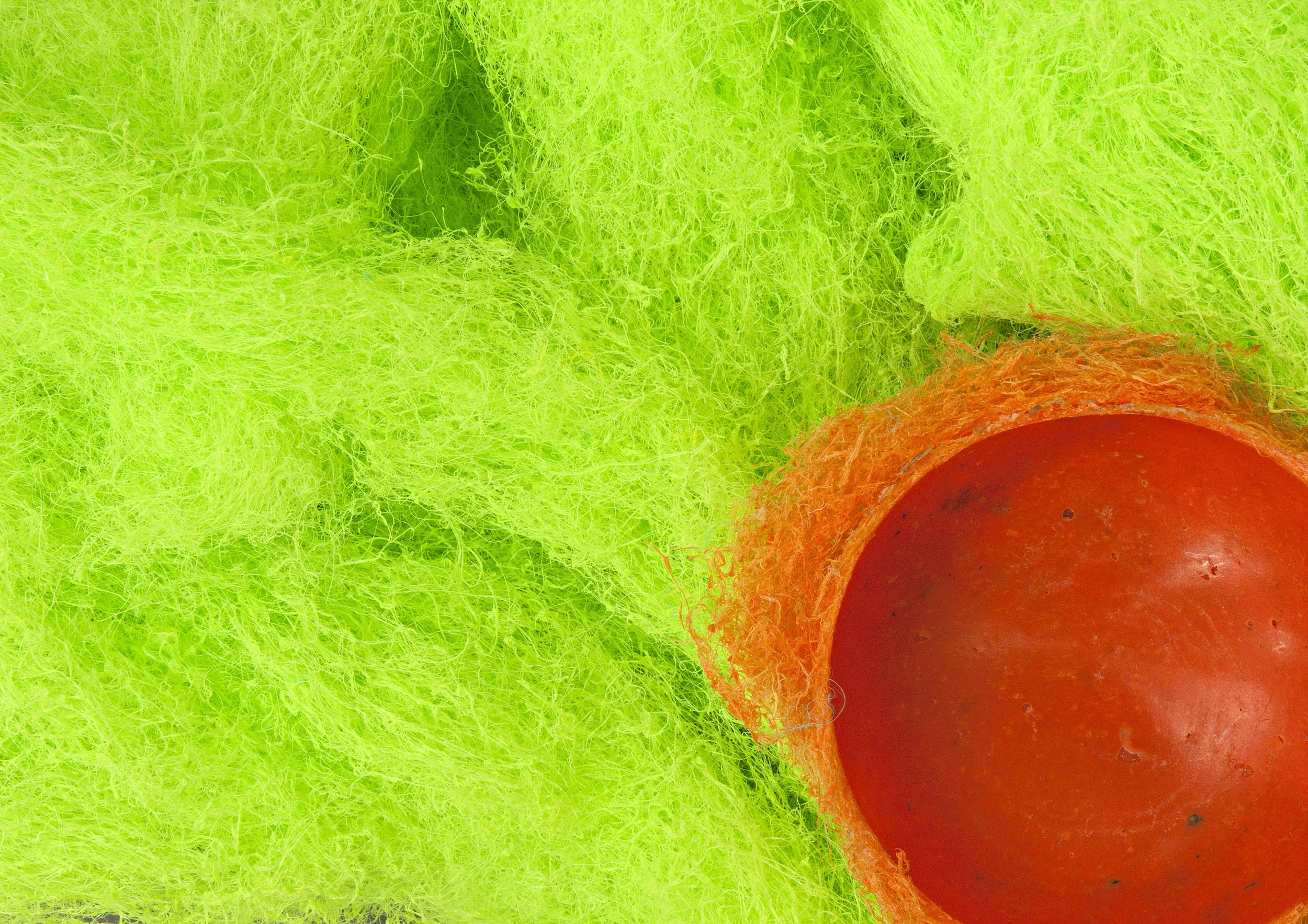

The Polyfloss Factory is a design and engineering ecological and social project, based around a technology that transforms plastic waste into new, valuable materials. Using a process inspired by cotton candy, the Polyfloss machine melts and spins discarded plastics into soft, versatile fibers. These fibers can be reshaped into textiles, insulation, or composite materials—offering a local, low-energy approach to recycling. By enabling small-scale, decentralized production, Polyfloss promotes a circular economy that connects communities, makers, and industries around sustainable material innovation.

Why Fibers ?

The specificity of plastic lies in its versatility. Unlike metal, wood or ceramics, it can easily take many different forms, like rigid or soft foam, film, fiber, weave. Making boards or bars of rigid plastic doesn’t provide many advantages compared to other materials. This is the first reason why we decided to invent a technology that could create foam and fibers. But we also realised that fibers was a form of material that was known all over the world. Every culture has its own techniques for using fibers to make textiles, objects or architectures. The knowledge is distributed, accessible and vibrant. Transforming chunks of waste plastic into fibers thus allows for the appropriation of this omnipresent material by communities, carftswomen and mens, and makers around the world.

Website of the project : www.thepolyflossfactory.com

The problem with plastics.

The production of virgin plastic still rises every year globally, reaching 400 million tons in 2025, while we still can’t recycle more than 10%. Every year, hundreds of million of tons are accumulated in the oceans, soils and rivers around the world. The impacts on our fauna and flora, added to the sanitary and infrastructural issues this waste is generating is just insane. But these overall figures do not reflect the fact that the impacts of this pollution are not distributed evenly. While plastic pollution is not very visible in Occidental contexts, southern countries and their populations are directly affected and do not have the technical or infrastructural means to remedy the situation. Unlike other mass-manufactured materials, like metal, wood or cotton, plastic has been invented during the 20th century and immediatly deployed in industrial contexts. The knowledge and tools to select, transform and reuse it locally has not been distributed, and stays locked in highly specialized chemistry contexts. This is where Polyfloss, but also other initiatives like Precious Plastics, try to make a change.

A vibrant and engaged team.

Polyfloss has been created by a team of engineers and designers, motivated by the will to make a change : Audrey Gaulard, Christophe Machet, Nick Paget and Emile De Visscher, back in 2012 at the RCA. It became a company in 2021, after 10 years of R&D. Many institutions and companies supported the project along the way.

2

Part1. History of

the project

Part2. Technology

and products

Part3. Humanitarian

applications

1 _ The Polyfloss Factory, process with small ‘Rafale’ Machine, with help from Steven Akoun, 2018. Credits: The Polyfloss Factory.

2 _ The Polyfloss Factory, polyfloss foam and melted bowl, 2013. Credits: The Polyfloss Factory.