The polyfloss factory

PART 1 : Origins and history

1

1.1 Genealogy

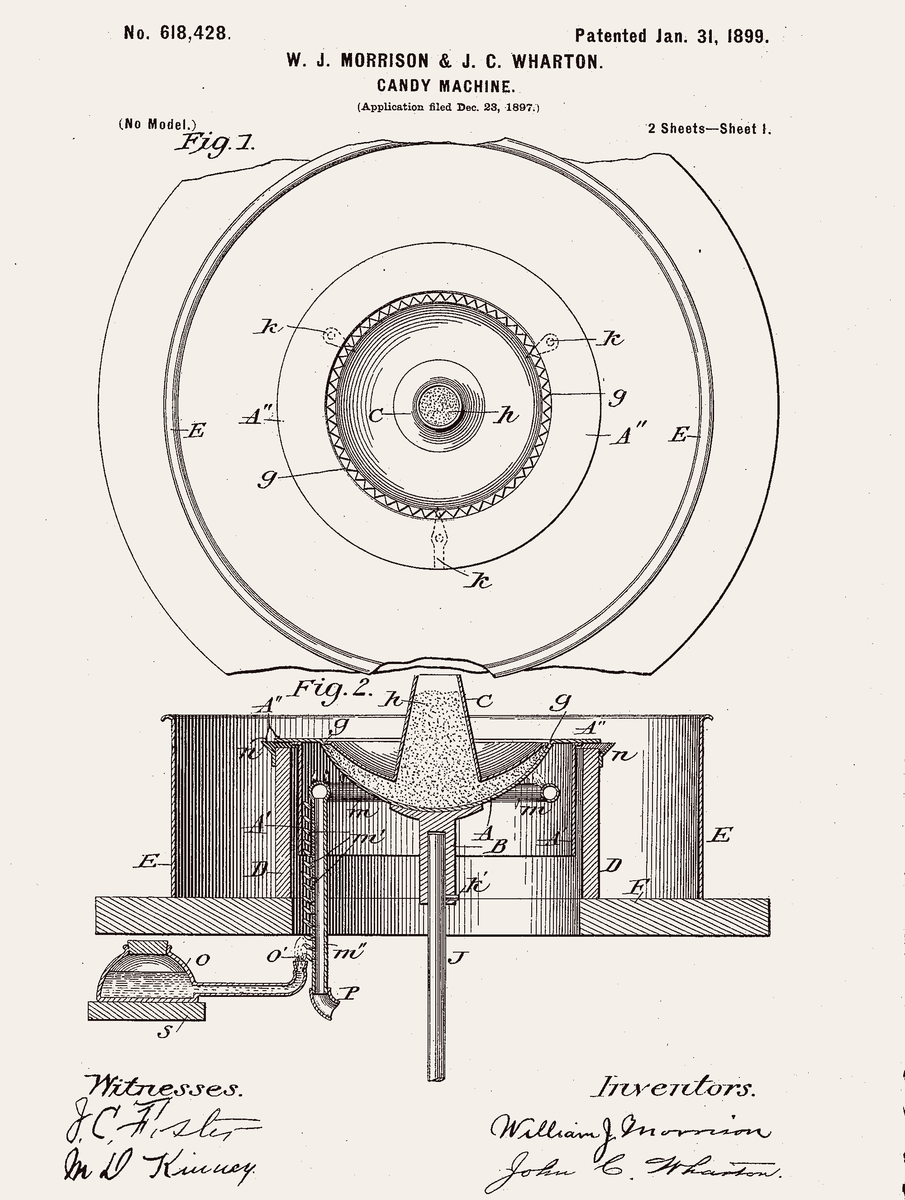

The histories of both cotton candy and plastic start back in the 19th century. The cotton candy technology was invented in 1897 by the dentist William J. Morrison and confectioner John C. Wharton in Nashville, Tennessee. Their device used heat and centrifugal force to melt sugar and spin it into thin, silky threads.

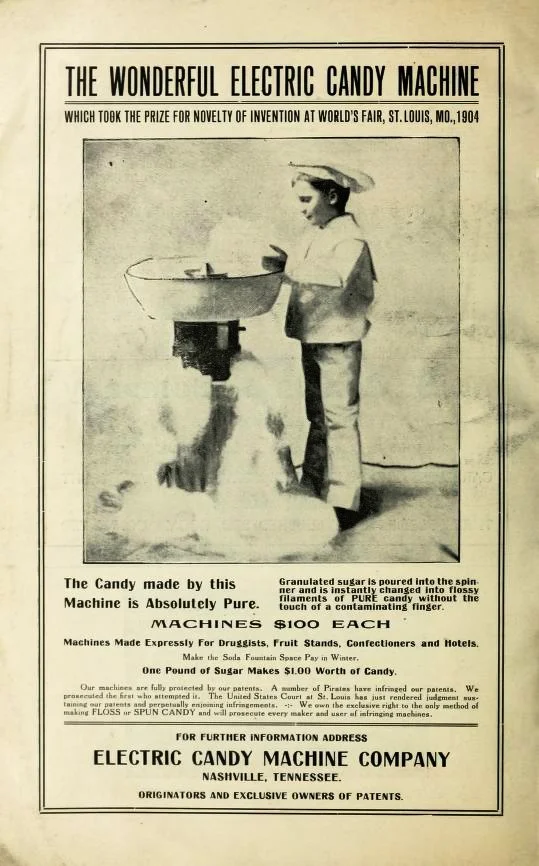

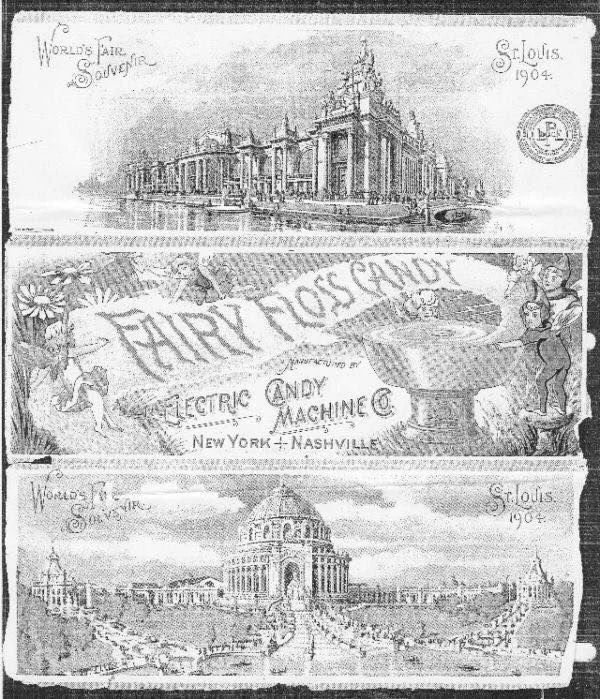

They unveiled their creation at the 1904 St. Louis World’s Fair, calling it Fairy Floss. The machine caused a sensation: more than 68,000 servings were sold during the exposition. This moment not only marked the birth of cotton candy—it also symbolized a new alliance between technology and delight, where engineering met wonder.

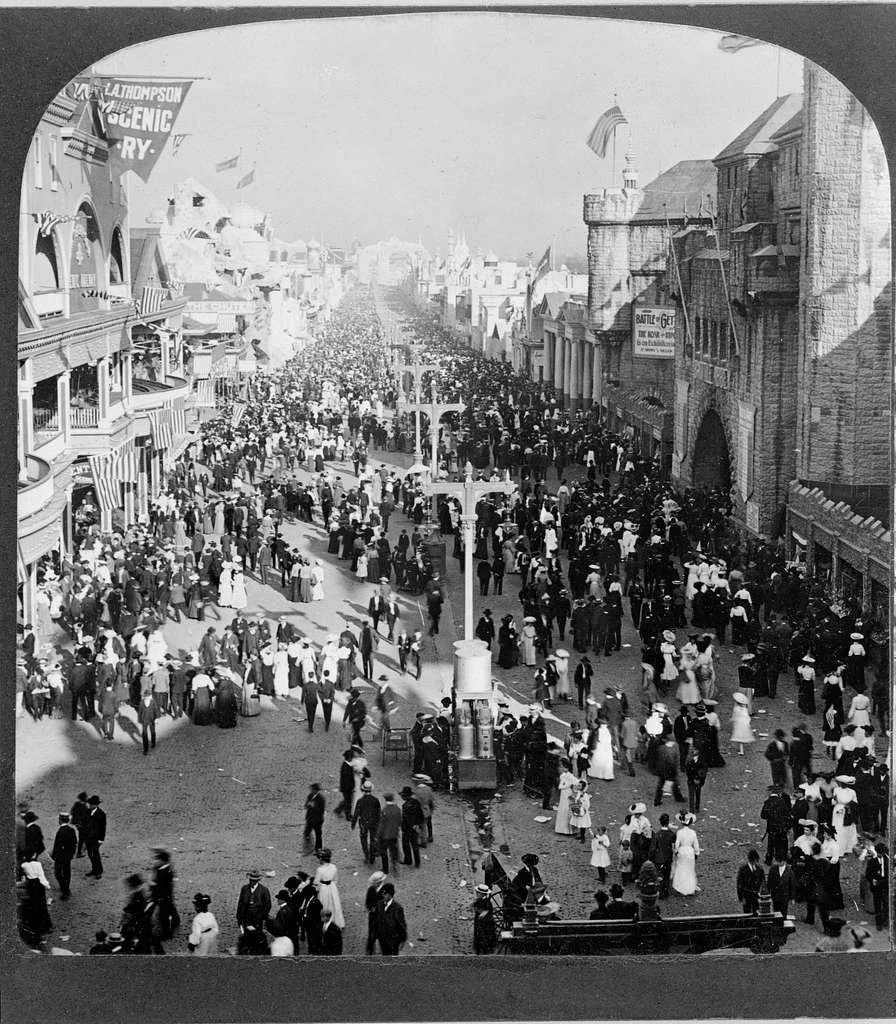

The St. Louis World’s Fair is the moment when the idea of the amusement park emerged. Among its most spectacular features was The Pike—a mile-long avenue of attractions, rides, and mechanical marvels that blended engineering with entertainment. It showcased the world’s first large-scale amusements: electric railways, moving panoramas, and fantastical architecture illuminated by thousands of lights. The Pike’s fusion of spectacle and technology inspired a new model for leisure culture—and several of the attractions where then transferred to the newly built Coney Island, central to New-York’s development model as highlighted by Rem Koolhaas in New York Delire.

2

3

4

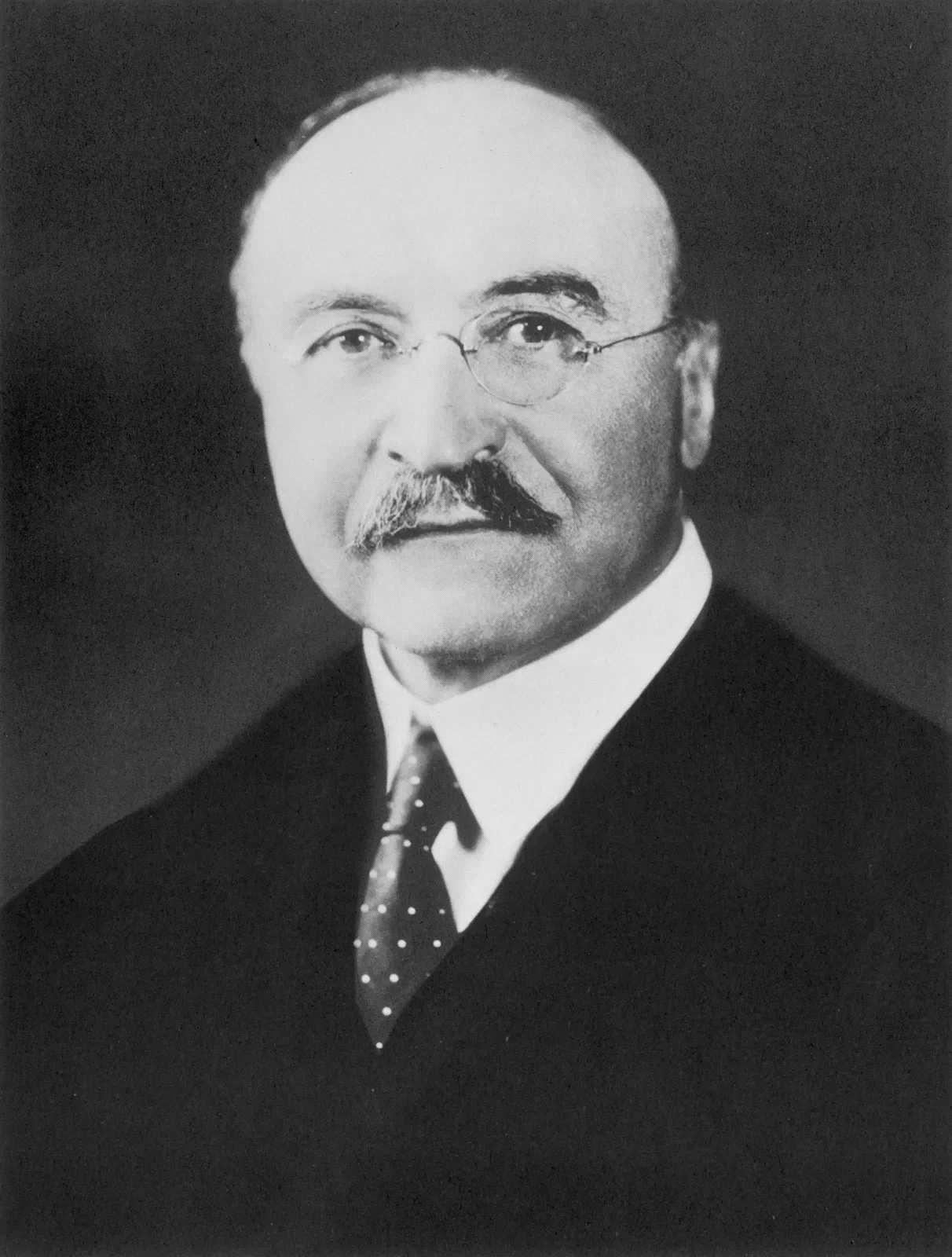

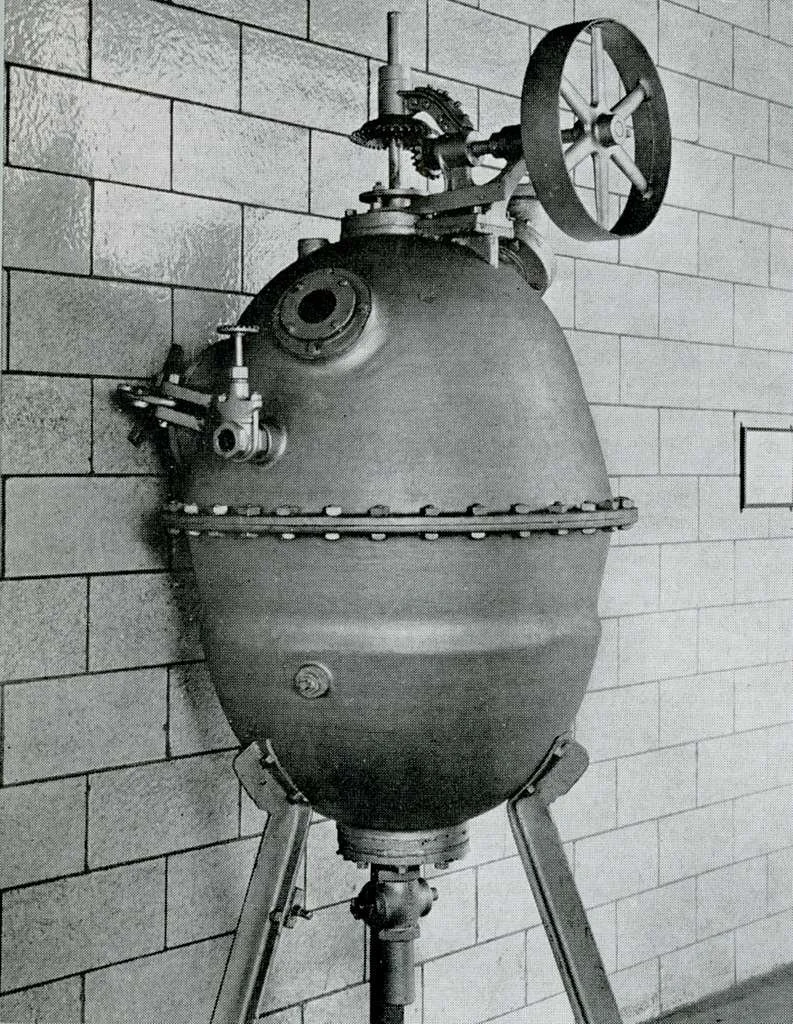

A few years later, Belgian-American chemist Leo Hendrik Baekeland created Bakelite, the first fully synthetic plastic, presented in 1907. By combining phenol and formaldehyde under heat and pressure in his lab in Yonkers, New-York, he produced a hard, moldable material that was heat-resistant and electrically insulating—a perfect fit for the modern age of telephones, radios, and electricity. Baekeland was looking for a way to replace natural gum for electric insulation. But Bakelite went much further than that. It marked the beginning of the plastic era: a material no longer derived from nature, but invented outright. It embodied the optimism of early industrial chemistry—when innovation promised endless new forms, colors, and possibilities.

What began as a miracle of modern chemistry soon became one of the planet’s greatest burdens. Since Baekeland’s first experiment in 1907, global plastic production has grown from just a few tons to over 400 million tons per year—and it continues to rise. Most of it is made from fossil fuels, and less than 10% is ever recycled. From deep oceans to mountain snow, plastic now circulates through every ecosystem on Earth. The same material that once symbolized human ingenuity has become a symbol of ecological overshoot—an urgent reminder that invention alone is not progress.

5

6

7

8

The two technologies, cotton-candy and plastic vulcanisation, started nearly in the same time and in the same region. But their development took very different paths and never directly met. The Polyfloss project makes a combinaison of both, a century after their invention.

9

1.2 Birth of the project

The idea of using the cotton-candy process to recycle plastics initially started in the Innovation Design Engineering MA program at the Royal College of Art and Imperial College London in 2011. Four students, Audrey Gaulard, Christophe Machet, Nick Paget and Emile De Visscher, were looking to find ways to locally upcycle plastic waste. After testing different methods like extrusion, heat-pressing or blow-molding, they figured out that plastic was the only industrial material that could produce affordable foam for all objects related to comfort. They thus tried to produce foam out of plastic waste. Facing technical difficulties with classic methods to make foam (with foaming agents), they had the idea of copying the cotton candy machine to make foam. After many iterations, they managed to make the process work and obtain their first plastic cotton candy machine, presented at Milan Design Week in 2012.

10

11

12

14

13

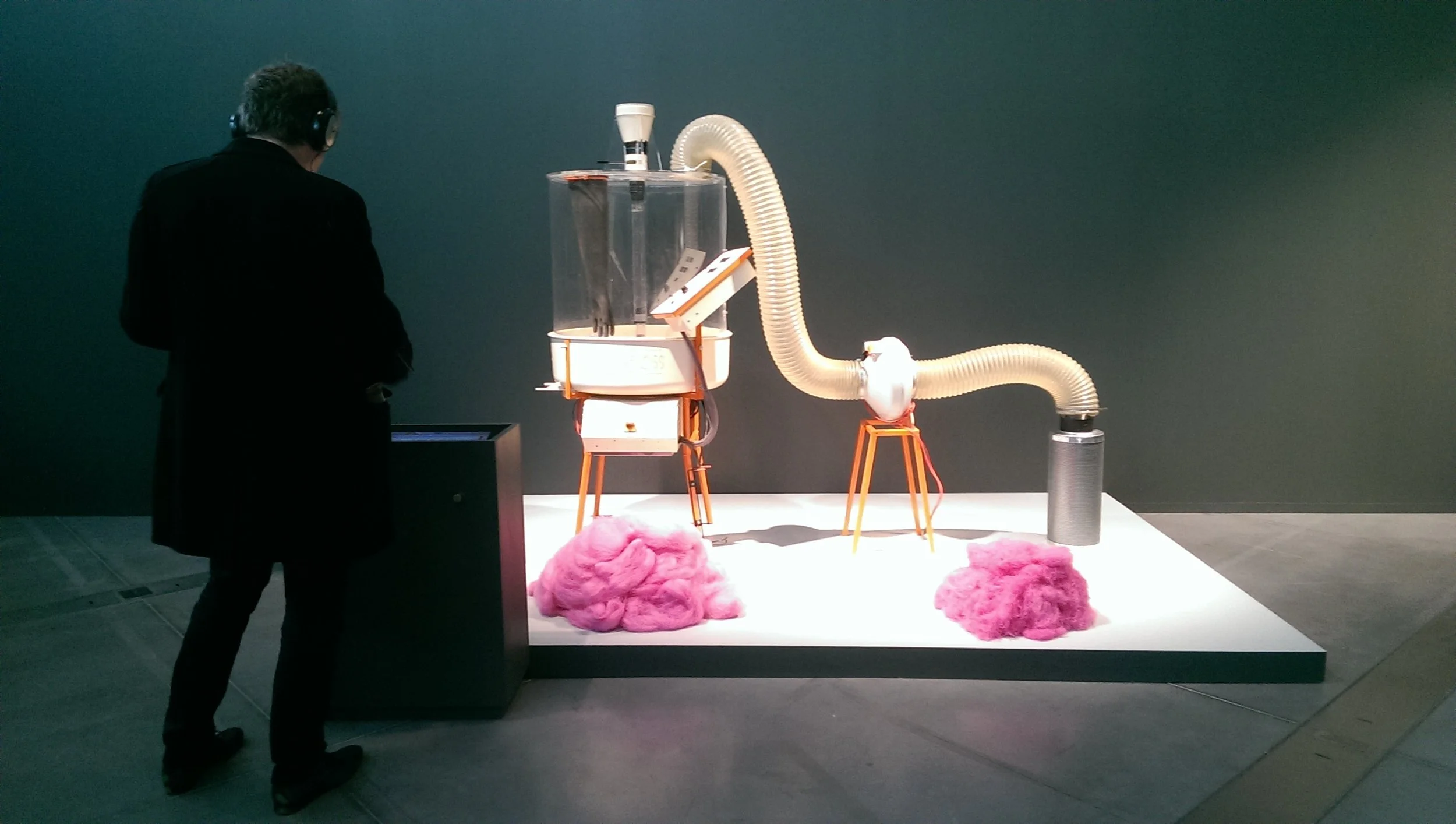

Recognition was immediate. Polyfloss was featured in magazines like WIRED, invited to conduct workshops in different architecture and design schools, and won several prizes. Between 2012 and 2017, the project got presented in more than 20 different exhibitions, commissioned for main installations, and travelled from London to Abu Dhabi, Shangai, or Seoul.

Museums and galleries are welcoming contexts for early ideas and prototypes, and presenting Polyfloss in all these venues was a motivation to continue and develop the project. But the ultimate aim of the project wasn’t to stay in these contexts - it needed to actually set up recycling initiatives and have an impact. To do so, the technology had to evolve from a crafted student project to a fully tested and industrial-standard fabrication machine.

15

Between 2011 and 2018, each new venue became an occasion to improve the technology and the quality of recycled fibers.

16

1.3 Technology development

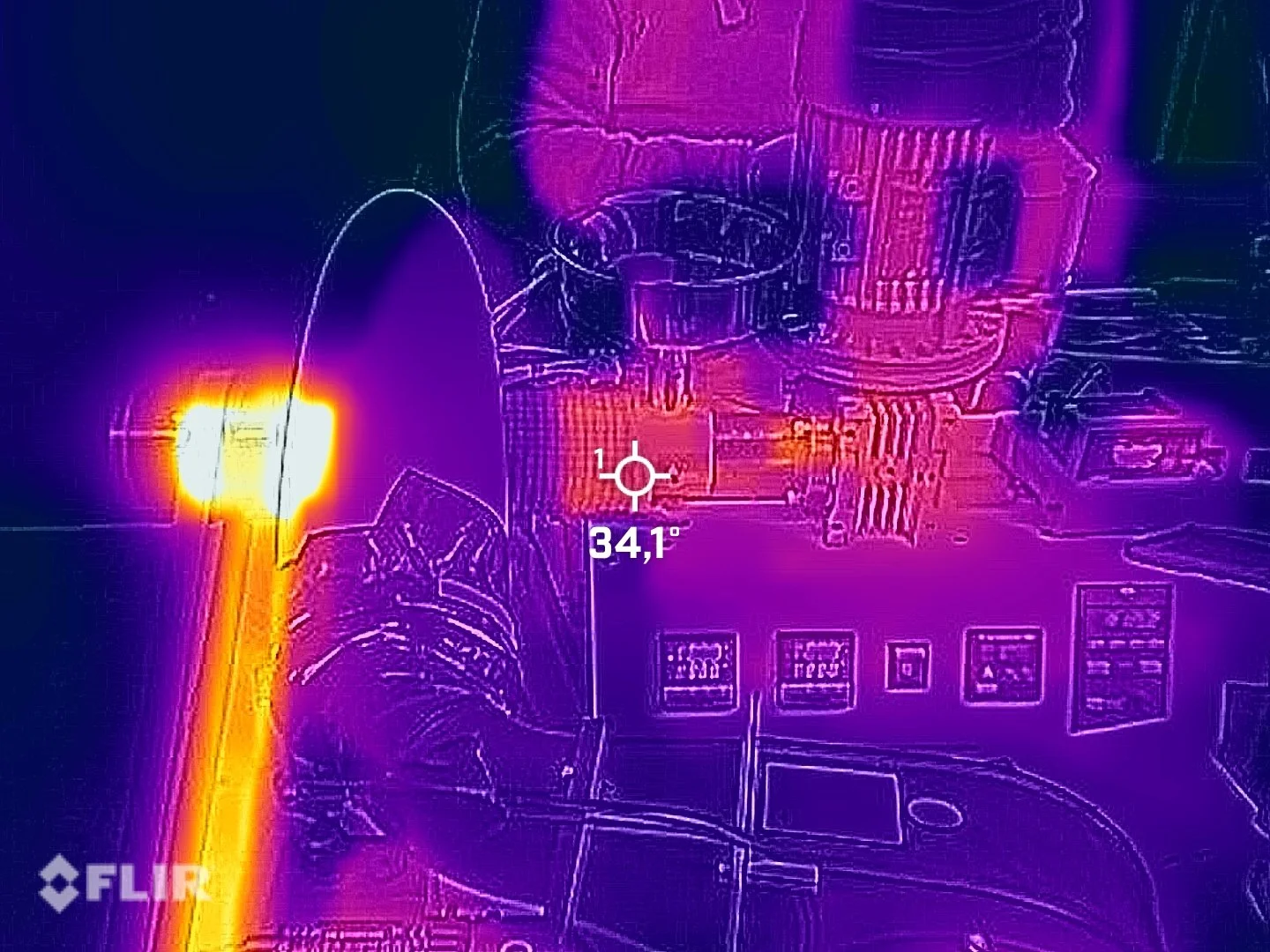

Over the years, experience and knowledge over the process advanced and the Polyfloss machine evolved from an early prototype to an automated, stable and consistent production tool. The principle stayed the same : spinning molten plastic in a chamber with tinny holes to generate fibers through centrifugation and blowing. The first machines used goz to heat the plastic in the chamber, while the latest ones used electricity to allow for a very precise control of temperature all over the process. The shape of the machine also evolved, from a vertical machine looking like its cotton-candy cousin, to a horizontal one allowing constant production flows. The technology is now fully functional and used in the field.

17

18

19

Research was conducted with support and expertise from different academic institutions, as well as public bodies of France and England. Each iteration of the Polyfloss machine allowed to develop an expertise on polymer sciences and processing, as well as extand the range of plastic used in the machine and the quality and regularity of the created fibers.

20

1 _ Morrison and Wharton's 1899 patent, Candy Machine. Credits: United States Patent Office.

2 _ Postal card of the Pike, Saint Louis World’s Fair, Missouri, 1904. Credits: CC.

3 _ The Louisiana Purchase Exposition, known as the St. Louis World's Fair, was an international exposition held in St. Louis, Missouri, from April 30 to December 1, 1904. Collection - Louisiana Purchase Exposition, 1904.

4 _ Poster promoting “the wonderfull electric candy machine”, 1904.

5 _ Engraving of The Pike, the amuzement park of the Saint-Louis World Fair Exhibition, 1904.

6 _ Portrait of Leo Hendrik Baekeland, 1916. Credits: Wikimedia Commons.

7 _ First semi-commercial Bakelizer, the vulcanizer to create Bakelite, 1935. Credits: public domain.

8 _ Early Bakelite telephone. Credits: Public Domain.

9 _ The Polyfloss Factory, Polyfloss machine “Ely”, at Saint-Etienne Design Biennale, 2015. Credits: Lucile Vareilles.

10 _ The Polyfloss Factory, Workshop tests and machining, at Royal College of Art London, 2013. Credits: The Polyfloss Factory.

11 _ The Polyfloss Factory, first presentation at Milan Salone del Mobile, part of the PARADIZE exhibition of the RCA graduates, 2012. Credits: The Polyfloss Factory.

12 _ The Polyfloss Factory, detail of one of the first prototypes, 2012. Credits: The Polyfloss Factory.

13 _ Up: The Polyfloss Factory, first presentation at Milan Salone del Mobile, part of the PARADIZE exhibition of the RCA graduates, 2012. Credits: The Polyfloss Factory. Down: The Polyfloss Factory, presented in the exhibition “Invention/Design, regards croisés”, at Musée des Arts et Métiers, 2016. Credits: Emile De Visscher.

14 _ The Polyfloss Factory presented in WIRED UK Magazine, 2012. Credits: WIRED UK.

15 _ The Polyfloss Factory, different exhibitions over the years (Valencia, Paris, London) between 2012 and 2018. Credits: The Polyfloss Factory.

16 _ Christophe Machet developing new parts for the Polyfloss machine, 2024. Credits: The Polyfloss Factory.

17 _ Thermal analysis of the latest Polyfloss machine development, to improve efficiency. Credits: The Polyfloss Factory.

18 _ Assembling of the mini-Polyfloss machine, Audrey Gaulard, 2025. Credits: The Polyfloss Factory.

19 _ Collection of Polyfloss in “Rafale” Polyfloss machine, 2014. Credits: The Polyfloss Factory.

20 _ Video of The Polyfloss machine in action, 2014. Credits: Plainview Studio.