The polyfloss factory

PART 2 : Technology and products

1

2.1. Machine principle

The polyfloss machine works like a cotton-candy : it spins molten plastic through tiny slits and elongates the generated droplets to create micrometer thick fibers. These fibers can be continuous or discrete, depending on the slit design.

The lastest versions of the Polyfloss machines are combined with an extruder to allow continuous production and precise control of temperature and throughput. The shredded waste plastic is first inserted in the hoppe at the back of the machine. The plastic falls into a barrel where it is heated to a predefined temperature and pushed through with a screw. The molten plastic then arrives in the spinning head and is ejected through a slit on the edge of the same head. The fibers are then elongated and cooled down by a flow of air generated by a bladeless fan. The fibers can then be collected on a panel or in a bag, but can also be furhter elongated on a rotating drum.

All the process is controlled with a custom made software and a tactile tablet - which controls the different motors (screw motor, fan motor and spinning motor) and the temperatures over the whole course of the plastic with PIDs. Power consumption and throughput can also be measured and recorded, and preventive maintenance protocols can be added.

2

3

The Polyfloss machine works best with PP and PET waste - which create, long, fine and soft fibers. It can also work with other polymers, but some may cause hazardous gazes when melted (like PS or ABS which releaze Styrene gaz, extremely dangerous to breathe) and others produce very fragile fibers, which tend to rapidly break and create microplastics - which is why it is better not to use them. PP and PET don’t have this problem, as they are safe to use within controlled temperature ranges, and are very flexible plastics, creating nice elastic fibers.

Two versions of the Polyfloss machine exist today : the mini version, a table top and automated machine processing around 1kg/h, and the standard pallet size version, processing up to 10kg/h.

4

5

The fibers created are collected at the output of the machine. Typically, the volume of the yarns is between 10 and 15 times larger than the pellets volume, opening interesting applications in insulation, packaging, and protection of fragile pieces. But the fibers can also be used as a textile, and be spun, woven, knitted, and felted with needles. It can also be remolded to create flexible sheets, rigid structures or compressed blocks like Expanded Polystyrene. The PP fibers also have excellent lypophilic qualities, meaning they can separate oil in water.

6

7

8

2.2. Polyfloss material and products

The fibers produced by the machine can be finetuned, depending on the plastic input and machine parameters. Fibers are typically ranging from 20 to 60 micrometers and can be continuous or about 20cm long. They can be collected as bulk on a grid, or on a rolling tube to get them all aligned.

The fibers can be used as such for insulation, packaging or stuffing. But they can also be used with textile techniques : threading, weaving, knitting or felting. Finally, they can be molded totally or partially to obtain rigid structures. One interesting technique that the Polyfloss team invented is heat-pressing, obtaining condensed pack of fibers that create light and self-standing objects, a bit like expanded polystyrene.

9

10

11

12

The wool created from Polyfloss is soft and extremely light, allowing to develop products and garments in different fields of applications. PP and PET don’t have the exact same properties, for example PP is lypophilic, allowing to extract oil in water - whereas PET is hydrophilic, capturing moisture in the air.

13

14

15

16

17

18

19

20

21

22

1 _ The Polyfloss Factory, Mini Machine, 2025. Credits: Palta Studio.

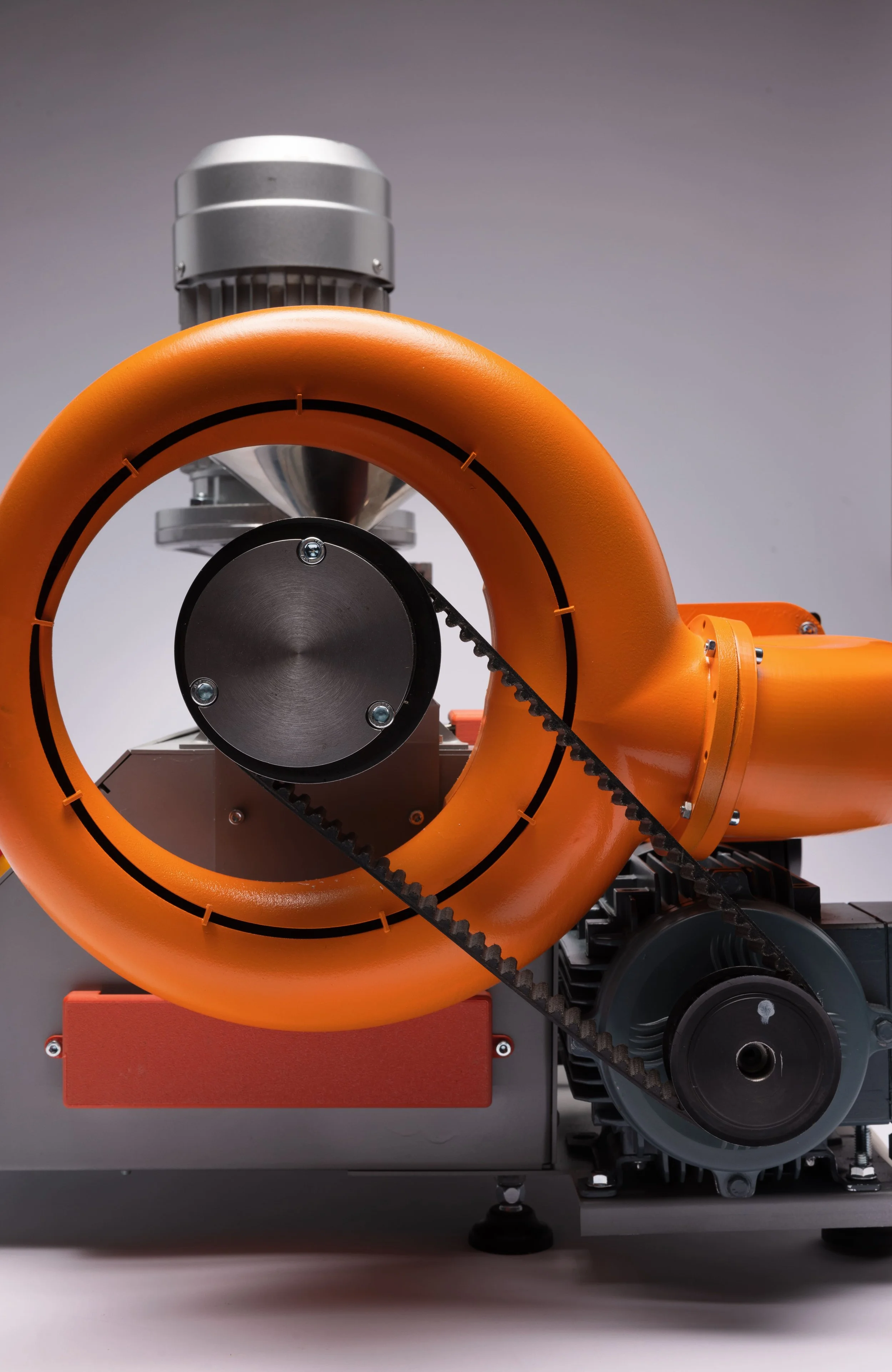

2 _ The Polyfloss Factory, Mini Machine, detail, 2025. Credits: Palta Studio.

3 _ The Polyfloss Factory, Mini Machine, detail poulie, 2025. Credits: Palta Studio.

4 and 5 _ The Polyfloss Factory founding team (A. Gaulard, C. Machet, E. De Visscher) and big machine, La Courneuve, 2025. Credits: The Polyfloss Factory.

6 _ The Polyfloss machine in action, producing fibers out of waste PP, 2024. Credits: The Polyfloss Factory.

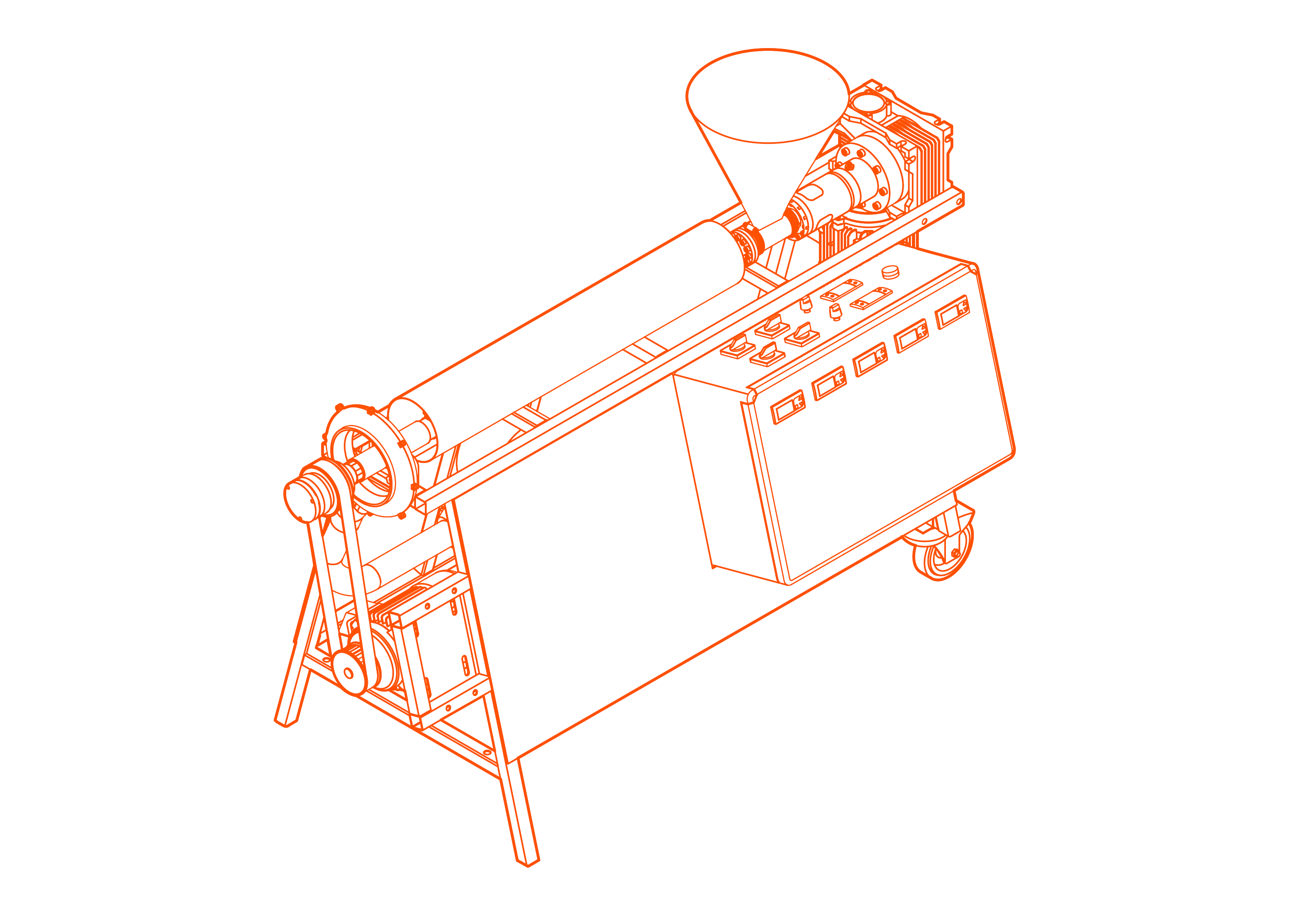

7 _ up: 500g of recycled fibers. Credits: The Polyfloss Factory. Down: wireframe of the Polyfloss Machine. Credits: Carla Donatti.

8 _ Setup of different products and prototypes made out of Polyfloss, with support from Steven Akoun, 2018. Credits: Palta Studio.

9 _ The Polyfloss Factory, detail of Polyfloss lamps, produced with support from Steven Akoun, 2018. Credits: Palta Studio.

10 _ The Polyfloss Factory, Polyfloss lamps, produced with support from Steven Akoun, 2018. Credits: Palta Studio.

11 _ The Polyfloss Factory, steps of transformation, 2025. Credits: Palta Studio.

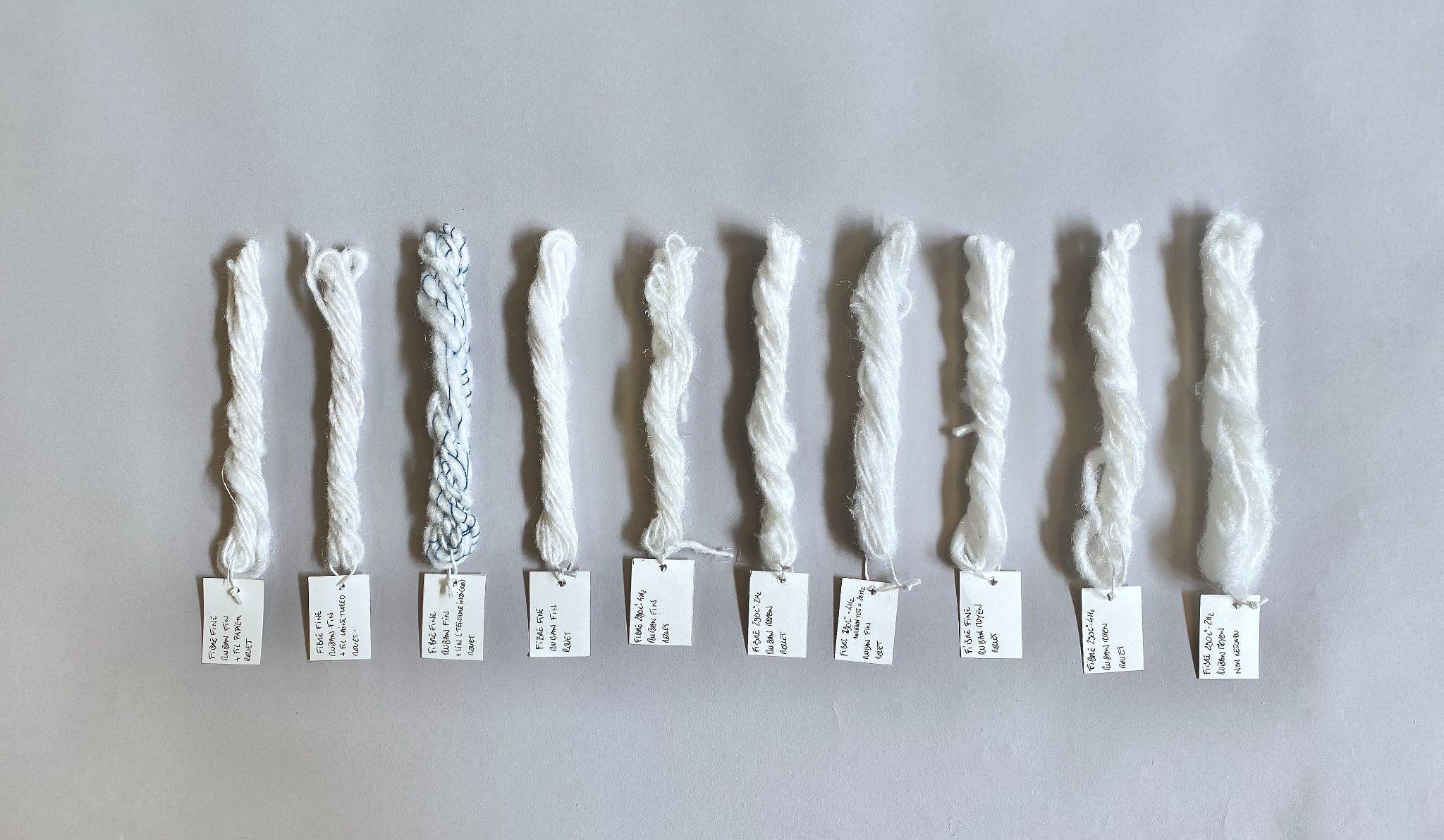

12 _ The Polyfloss Factory, fibers and threads, 2025. Credits: Palta Studio.

13 _ textile produced from Polyfloss fibers and linen, part of ENSAD workshop in 2015, organised by Aurelie Mossé. Credits: Sophie Allard.

14 _ Different threads produced from Polyfloss recycled fibers, 2022. Credits: The Polyfloss Factory.

15 _ Polyfloss compressed bricks, lightweight and rigid material, recycled polypropylene, conducted as a result of Design International research workshop, UQAM, 2022. Credits: The Polyfloss Factory.

16 _ The Polyfloss Factory, knitted Polyfloss out of a waste plastic chair, presented at Victoria and Alberts V&A Late event, 2014. Credits: The Polyfloss Factory.

17 _ The Polyfloss Factory, tufting of Polyfloss material, with support from Jude Zantain, 2022. Credits: The Polyfloss Factory.

18 _ The Polyfloss Factory, samples of textiles made out of Polyfloss recycled plastic, with support from Jude Zantain, 2022. Credits: The Polyfloss Factory.

19 _ The Polyfloss Factory, Polyfloss material pressed with an iron and laser-cutted, part of the Ateliers Partagés workshop at ENSAD, conducted by Aurélie Mossé, 2016. Credits: The Polyfloss Factory.

20 _ The Polyfloss Factory, blue Polyfloss material, 2025. Credits: Palta Studio.

21 _ The Polyfloss Factory, Polyfloss lamp, design Christophe Machet, 2020. Credits: Christophe Machet.

22 _ The Polyfloss Factory at Rehogar Spain exhibition, 2014. Credits: The Polyfloss Factory.