The polyfloss factory

PART 3 : HUMANITARIAN APPLICATIONS

1

3.1 Empowering local communities

Because Polyfloss is a small-scale plastic-recycling technology opening a wide variety of applications, it soon became relevant to operate in contexts where conventional waste-management systems are absent or severely limited. Starting in 2018, Polyfloss teamed up with several NGOs and association to deploy machines in humanitarian and development contexts. By transforming locally available plastic waste into lightweight fibers, the system offers materials suitable for insulation, textile craft, or filtering application—functions that can directly support everyday needs in remote, crisis-affected, or resource-constrained environments.

Its compact format, low energy requirement, resilience and flexibility toward different polymer types make it particularly suited to humanitarian settings where logistical capacity is limited and material scarcity is acute. By doing so, it also empowers local communities to transform a critical waste into a new resource.

2

3.2 PIPER project in Nepal

The latest project took place in Nepal, together with World Vision International Nepal and the Response Innovation Lab. A machine was installed in the west region of Dhangadhi, and local re-insertion assocations were trained to use the machine and setup a circular economy with plastic. The Polyfloss is then used for insulation, by placing it into woven bags and inserted into plaster walls, ensuring fire-resistance. 25 school rooms have been insulated thanks to the project up to now. A further phase of the project would involve several production center in other regions of Nepal.

3

4

5

6

7

8

9

10

11

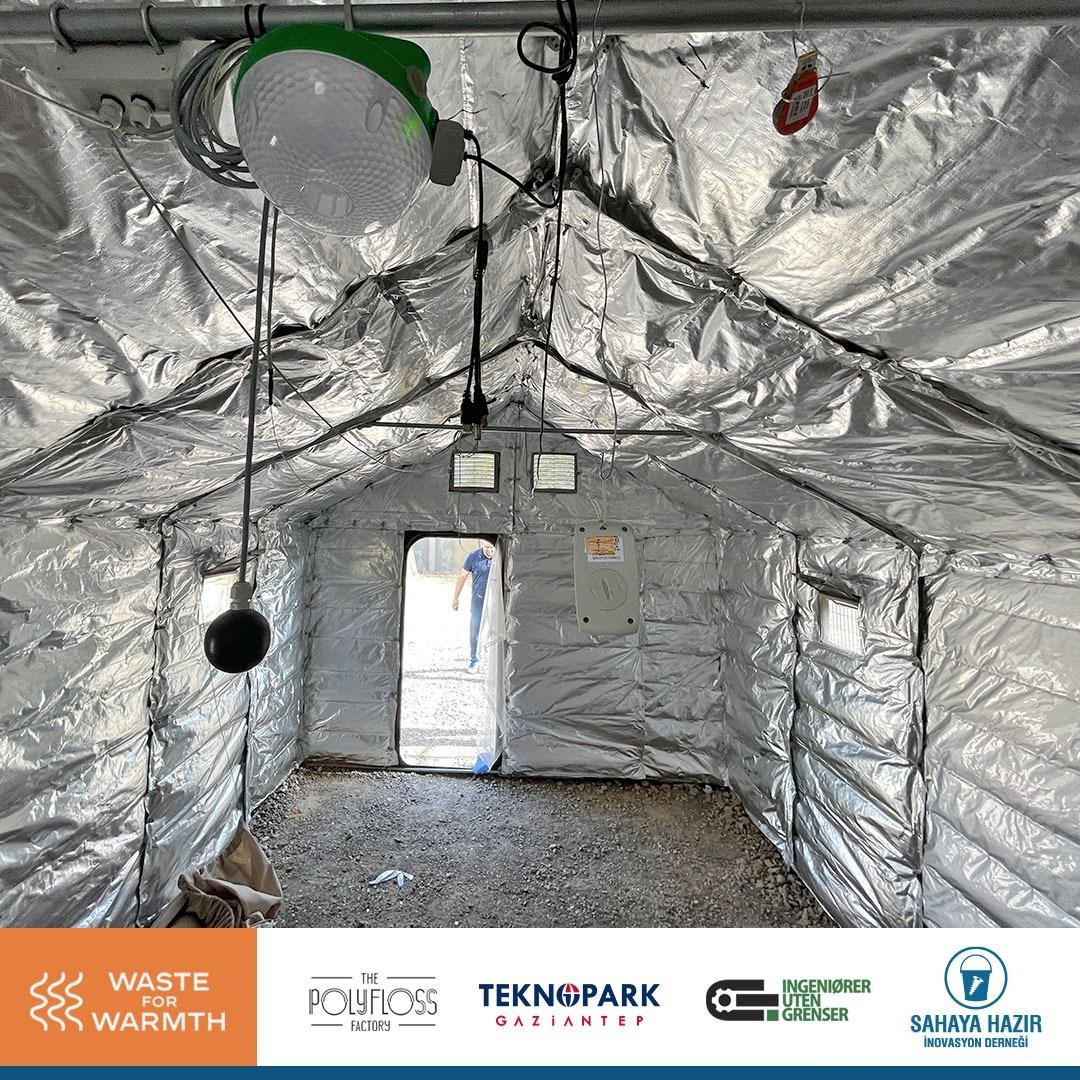

3.3 Waste 4 Warmth

Another big humanitarian initiative was called Waste 4 Warmth. Gathering 3 structures (Engineers Without Borders Norway, Field Ready Turkey and Polyfloss), we looked at ways to use Polyfloss as an emergy response to cold environments for refugees. The project was funded by the Innovation in Humanitarian Grant from Innovate Norway, between 2018 and 2022. A brand new machine was designed, built and sent to Gazientep, the main city near the syrian borders in Turkey. Our colleagues from Field Ready and Engineers Without Borders then transformed more than 2 tons of waste plastic into insulation flexible panels, encapsulated into tarpolin sheets. These sheets were then installed in about 30 houses in Syria and Turkey for refugees. The measurment of the resulting insulation could be done in winter and summer time, proving that the solution could reduce the temperature peaks by up to 10°C.

Website of the project can be found here : https://www.waste4warmth.org/

12

13

14

15

16

17

Several other projects took place within the consortium of Waste 4 Wamrth, like projects with the FabLab Nepal and Green Environment Lab in Kathmandu, or an upcoming project with UNOPS in Sudan, where the machines have already been shipped.

In parallel, another project took place with Polyfloss in Madagascar since 2018, part of the Ndao Hanavao project funded by Rubis Mécénat Foundation and Vitogaz Madagascar. More informations to be found here.

18

Along the last 10 years, many NGOs and public institutions supported Polyfloss in this attempt to transfer Polyfloss in regions and contexts where it’s actually needed the most.

1 _ PIPER Project, training session, The Polyfloss Factory, World Vision International Nepal and the Response Innovation Lab, Nepal, 2024. Credits: The Polyfloss Factory.

2 _ PIPER Project, video of the recycling installation, The Polyfloss Factory, World Vision International Nepal and the Response Innovation Lab, Nepal, 2024. Credits: The Polyfloss Factory.

3 _ PIPER Project, local team and local maire advisor with the machine, The Polyfloss Factory, World Vision International Nepal and the Response Innovation Lab, Nepal, 2024. Credits: The Polyfloss Factory.

4 _ PIPER Project, local waste plastic, The Polyfloss Factory, World Vision International Nepal and the Response Innovation Lab, Nepal, 2024. Credits: The Polyfloss Factory.

5 _ PIPER Project, training and explanation of the machine maintenance protocols, The Polyfloss Factory, World Vision International Nepal and the Response Innovation Lab, Nepal, 2024. Credits: The Polyfloss Factory.

6 _ PIPER Project, travelling to the village, The Polyfloss Factory, World Vision International Nepal and the Response Innovation Lab, Nepal, 2024. Credits: The Polyfloss Factory.

7 _ PIPER Project, presentation of the initiative to local actors and entrepreneurs, The Polyfloss Factory, World Vision International Nepal and the Response Innovation Lab, Nepal, 2024. Credits: The Polyfloss Factory.

8 _ PIPER Project, hardware shop, The Polyfloss Factory, World Vision International Nepal and the Response Innovation Lab, Nepal, 2024. Credits: The Polyfloss Factory.

9 _ PIPER Project, school insulated with recycled fibers, The Polyfloss Factory, World Vision International Nepal and the Response Innovation Lab, Nepal, 2024. Credits: The Polyfloss Factory.

10 _ PIPER Project, waste source, The Polyfloss Factory, World Vision International Nepal and the Response Innovation Lab, Nepal, 2024. Credits: The Polyfloss Factory.

11 _ PIPER Project, end of the day in Nepal, The Polyfloss Factory, World Vision International Nepal and the Response Innovation Lab, Nepal, 2024. Credits: The Polyfloss Factory.

12 _ W4W Syrian project, presentation video, The Polyfloss Factory, Engineers Without Borders Norway and Field Ready Turkey, 2021. Credits: Field Ready Turkey.

13 _ W4W project, tent insulation in Gazientep, The Polyfloss Factory, Engineers Without Borders Norway and Field Ready Turkey, 2022. Credits: Field Ready Turkey.

14 _ W4W project, tent insulation testing in Norway, The Polyfloss Factory, Engineers Without Borders Norway and Field Ready Turkey, 2020. Credits: Engineers Without Borders Norway.

15 _ W4W project, measurments of differences between insulated and non-insulated tents, Gazientep, Turkey, 2020. Credits: Field Ready Turkey.

16 _ W4W project, semi-rigid tents from IOM, insulated with Polyfloss and tarpolin, Gazientep, Turkey, 2020. Credits: Field Ready Turkey.

17 _ W4W Project, places where the machines have been installed and done recycling operations, between 2020 and 2024. Credits: Waste 4 Warmth.

18 _ Ndao Hanavao, social project in Madagascar, financed by Rubis Mécénat and Vitogaz Madagascar, 2018-2021. Credits: Rijasolo.