PEARLING Is A slow dip coating process, allowing to build artiFiCIal nacre of any geometry.

1

When thinking about alternative local manufacturing processes, the geographic question also becomes a temporal question, as local communities don’t require renewal of their objects regularly. This lead to explore fabrication processes where value is linked to time - where waiting becomes synonym of preciosity. That is the case of pearls, which require time to grow within the oyster.

Based on several scientific articles suggesting procedures to copy the process of mother-of-pearl growth, Emile De Visscher adapted the process to imagine a slow-manufacturing machine which can coat any shape or surface - but it that takes about 6 months to create 1mm of material. The machine itself thus becomes a performance, working on a clockwork principle.

2

3

4

5

6

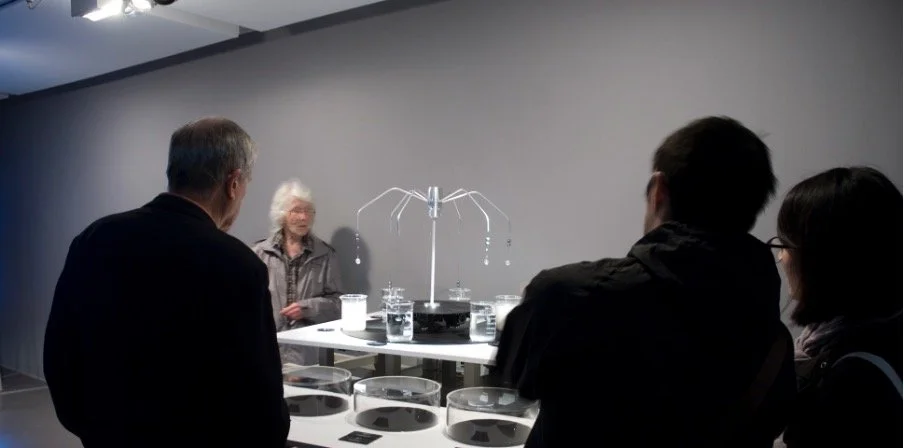

The process itself became interesting when exhibited, engaging discussions with visitors. Some didn’t want to see a mechanisation of pearls - and preferred the natural origin of the jewels. But looking at the manufacturing methods of pearls, which today are all farmed with artifical balls inserted in the oysters, raised the question of animal well-being compared to machine manufacturing.

7

The process was then used to coat 3D printed hollow pieces, to explore the potential of rapid prototyping combined with slow finalization.

8

9

10

11

12

1 _ Emile De Visscher, Pearling Machine 2.0, Fondation EDF, exhibition ALIVE, 2014. Credits : Emile De Visscher.

2 _ Emile De Visscher, samples of layered mother-of-pearl tests, Final Show Exhibition, Royal College of Art, 2012. Credits: Emile De Visscher.

3 _ Emile De Visscher, Pearling Machine 2.0, detail, Fondation EDF, exhibition ALIVE, 2014. Credits : Emile De Visscher.

4 _ Emile De Visscher, first pearls produced in the exhibition, Fondation EDF, exhibition ALIVE, 2014. Credits : Emile De Visscher.

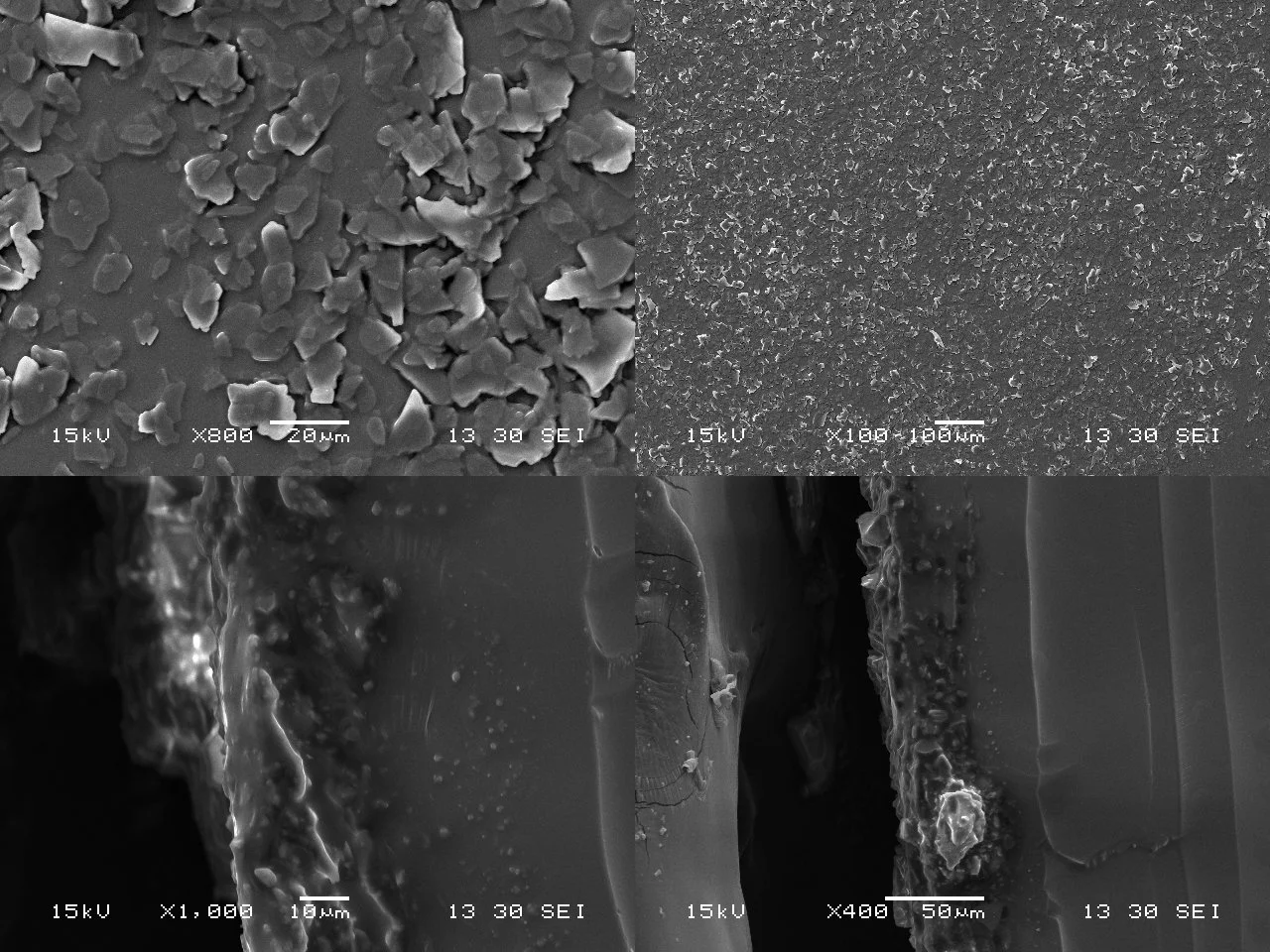

5 _ Microscop image of the pearl tests, conducted at Imperial College London, 2012. Credits: Emile De Visscher.

6 _ Emile De Visscher, Pearling machine 1.0, Final Show Exhibition, Royal College of Art, 2012. Credits: Emile De Visscher.

7 _ Pearling Machine 2.0 at Fondation EDF, exhibition ALIVE, 2014. Credits : Emile De Visscher.

8 _ Emile De Visscher, 3D printed structure with mother-of-pearl finish, 2016. Credits: Palta Studio.

9 _ Emile De Visscher, 3D printed bowl with mother-of-pearl finish, 2016. Credits: Palta Studio.

10 _ Emile De Visscher, scene of objects in 3D prints and pearling finish, 2016. Credits: Palta Studio.

11 _ Emile De Visscher, detail of objects in 3D prints and pearling finish, 2016. Credits: Palta Studio.

12 _ Emile De Visscher, 3D prints and pearling finish, 2016. Credits: Palta Studio.